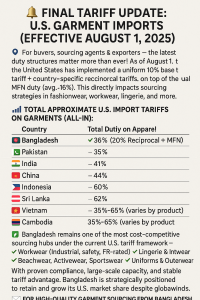

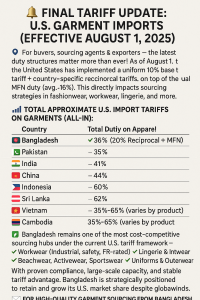

U.S. Garment Import Tariff Breakdown

Country-wise Tariff Imposition Summary 🌍 Other Countries:

🧾 Garments Cost of Making (CM): Overview

In the garment manufacturing industry, CM (Cost of Making) refers to the cost incurred to manufacture one garment, excluding the cost of fabric and trims. It includes all fixed and variable expenses related to factory operations.

CM is crucial for:

• Determining the selling price

• Controlling production costs

• Maximizing profit

⸻

🔢 Formula for Monthly Garments Cost of Making (CM)

CM per piece =

{Monthly Total Factory Cost (Fixed + Variable)}÷

{Monthly Total Production (pieces)}

⸻

✅ Example 1: Standard Method

Given:

Particulars Amount (BDT)

⸻ ⸻ ⸻ ⸻ ⸻ ⸻ ⸻ ⸻

Salary & Wages 20,000,000

Bank Loan Interest 100,000

Depreciation 50,000

Building Rent 200,000

Transportation Cost 150,000

Repair & Maintenance 50,000

Utility Expenses (Total) 1,000,000

⸻ ⸻ ⸻ ⸻ ⸻ ⸻ ⸻ ⸻

Total Monthly Cost 21,550,000

Production Details:

Particular Value

⸻ ⸻ ⸻ ⸻ ⸻ ⸻ ⸻ ⸻

No. of Machines 150

Hourly Capacity (per machine) 30 pieces

Working Hours per Day 8 hours

Working Days per Month 26 days

⸻ ⸻ ⸻ ⸻ ⸻ ⸻ ⸻ ⸻

Total Monthly Production 936,000 pieces

{150 × 30 × 8 × 26}

Calculation:

CM per piece

= {21,550,000}÷{936,000}

= {Tk. 23.02}

⸻

✅ Example 2: Effective Method (SMV-based)

Factory & Production Setup:

Particulars Value

⸻ ⸻ ⸻ ⸻ ⸻ ⸻ ⸻ ⸻

Total No. of Machines 180

No. of Workers 200

Working Hours/Day 8

Working Days/Month 26

Efficiency Level 65%

SMV per Garment (Trouser) 35 minutes

Step 1: Available Minutes (monthly)

= 200 × 8 × 26 × 60 × 65% = 1,622,400 minutes

Factory Cost Breakdown:

Cost Item Monthly Cost Cost per Minute (Tk.) (Tk.)

⸻ ⸻ ⸻ ⸻ ⸻ ⸻ ⸻ ⸻

Salary & Wages 4,000,000 2.47

Interest 100,000 0.06

Depreciation 50,000 0.03

Rent 200,000 0.12

Transportation 150,000 0.09

Repair &

Maintenance 50,000 0.03

Utilities 1,000,000 0.62

⸻ ⸻ ⸻ ⸻ ⸻ ⸻ ⸻ ⸻

Total Per Minute Cost — 3.42

Step 2: Calculate CM for Trouser

{CM} = 35 minutes × 3.42Tk/minute

={Tk. 119.70}

⸻

✅ Example 3: Sewing Line CM Calculation

Given:

Particulars Value

⸻ ⸻ ⸻ ⸻ ⸻ ⸻ ⸻ ⸻

No. of Operators 30

No. of Helpers 5

Avg. Operator Salary Tk. 10,000

Avg. Helper Salary Tk. 8,000

Working Days 26

Working Hours/Day 8

Step 1: Salary Expense

= (30 × 10,000) + (5 × 8,000) = 340,000 Tk/month

Step 2: Available Minutes per Month

= (30 + 5) × 8 × 60 × 26 = 436,800 minutes

Step 3: Cost per Minute

={340,000}÷{436,800} = 0.78 Tk/minute

Step 4: CM for a Garment (SMV = 45 min)

= 0.78 × 45 ={Tk. 35.10}

⸻

✅ Summary Table

Method CM per Piece (Tk.)

Standard Factory Method 23.02

Effective (SMV-Based) 119.70

Sewing Line Specific 35.10

Note: All these costing information is arbitrarily taken, so these values are not actual costing value.

Country-wise Tariff Imposition Summary 🌍 Other Countries:

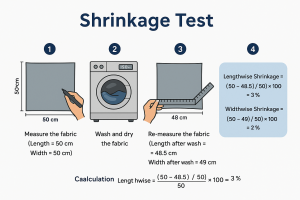

🔍 What is Fabric Shrinkage? Shrinkage refers to the reduction in the dimensions (length and/or width) of fabric after it

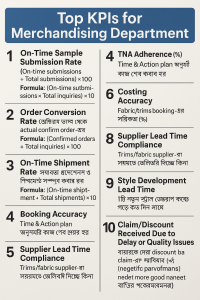

✅ Top KPIs for Merchandising Department (with Bangla Explanation): 1. On-Time Sample Submission Rate📌 সময়মতো বায়ারকে স্যাম্পল সাবমিটের হার📊 Formula:

📖 Index 📚 Introduction of Merchandising 📚 Responsibility of Merchandising 📚 A Merchandiser Daily Work 📚 Email Writing 📚 Marketing

Empowering learners with curated online courses designed to build real-world skills in just 60 days.