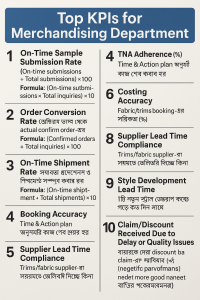

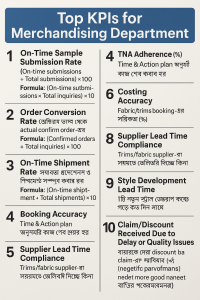

Top KPIs for Merchandising Department

✅ Top KPIs for Merchandising Department (with Bangla Explanation): 1. On-Time Sample Submission Rate📌 সময়মতো বায়ারকে স্যাম্পল সাবমিটের হার📊 Formula:

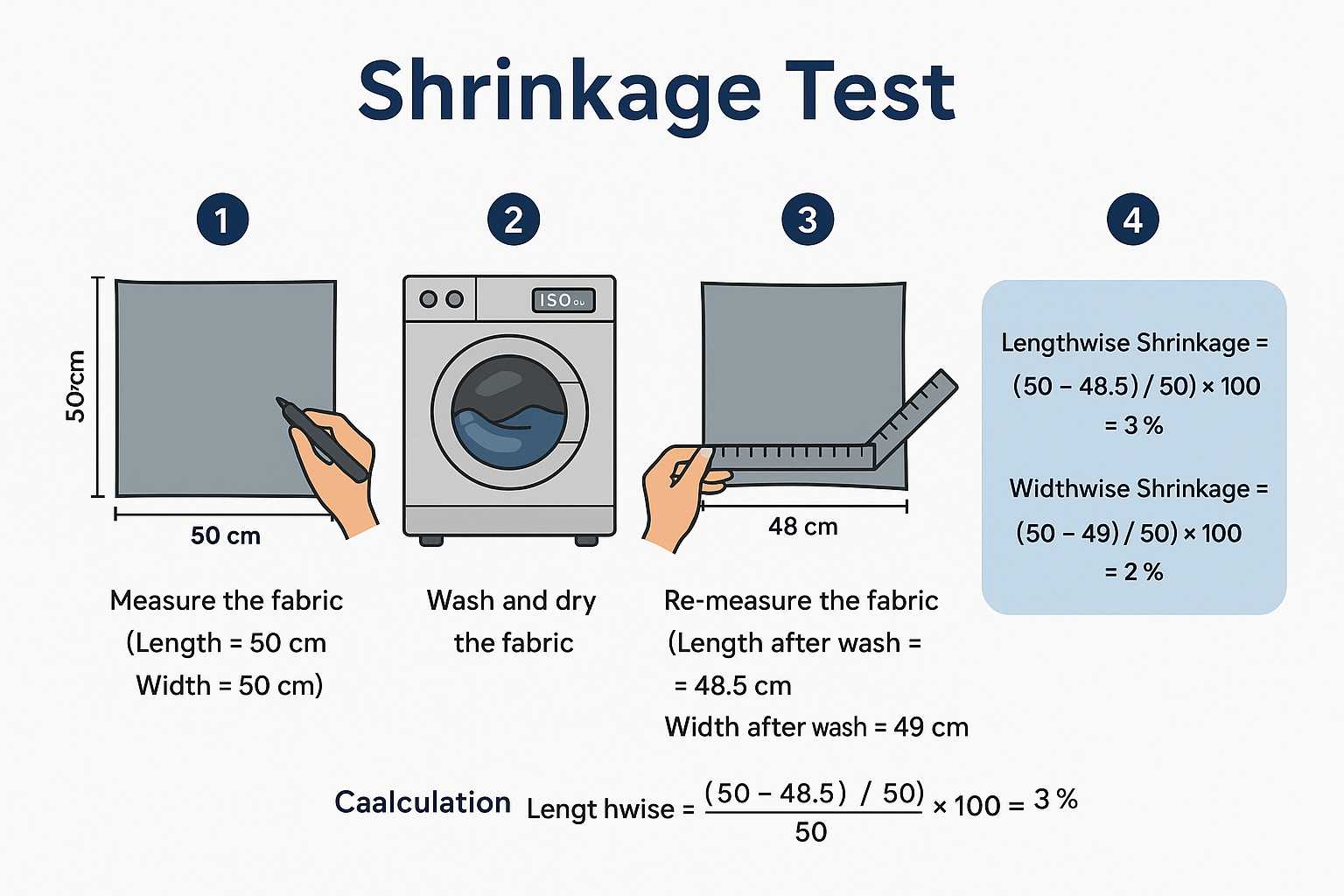

Shrinkage refers to the reduction in the dimensions (length and/or width) of fabric after it is washed, dried, or processed. It is a critical factor in the garment industry because excessive shrinkage can distort the garment’s fit, measurement, and appearance.

Shrinkage usually occurs in three ways:

Let’s go through a standard shrinkage test procedure with an example.

(50−48.550)×100=3%\left(\frac{50 – 48.5}{50}\right) × 100 = 3\%(5050−48.5)×100=3%

(50−4950)×100=2%\left(\frac{50 – 49}{50}\right) × 100 = 2\%(5050−49)×100=2%

| Fabric Type | Acceptable Limit |

|---|---|

| Knitted | ±5% or less |

| Woven | ±3% or less |

✅ Top KPIs for Merchandising Department (with Bangla Explanation): 1. On-Time Sample Submission Rate📌 সময়মতো বায়ারকে স্যাম্পল সাবমিটের হার📊 Formula:

📖 Index 📚 Introduction of Merchandising 📚 Responsibility of Merchandising 📚 A Merchandiser Daily Work 📚 Email Writing 📚 Marketing

🧾 Garments Cost of Making (CM): Overview In the garment manufacturing industry, CM (Cost of Making) refers to the cost

Why Quality Buyer Data is the Backbone of Garment Export Success IntroductionIn the highly competitive garment industry, the difference between

Empowering learners with curated online courses designed to build real-world skills in just 60 days.