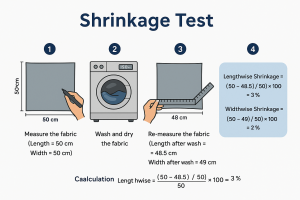

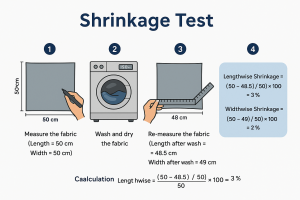

Fabric Shrinkage Test

🔍 What is Fabric Shrinkage? Shrinkage refers to the reduction in the dimensions (length and/or width) of fabric after it

1. Obtain details Tech Pack from buyer.

2. Analyze the Tech pack and find out all risk factors, then –

a) Costing

b) Development Sampling

For Costing:

i) Do consumption from Cad.

ii) Collect the price of all the required Trims and & fabrics.

iii) Collect required data from IE (like -Thread Consumption, Operation Bulletin (OB), SMV, Productivity, Efficiency)

3. Do Initial Costing as well as make ready development Sample

4. Send Costing & sample to buyer for reviewing and comments.

5. If sample (Dev) and costing approved then have to confirm the order, but if not, have to re-do.

6. Collect final update Art-work and start for Lab Dip / Strike off/Desk-loom development as per requirement.

7. If approved above all, will get /collect the final Purchase Order (PO)from Buyer with details.

i) According TOD/CRD make a proper T & A (Time & action).

ii) Sit/Mail with Planning concern to book production space as per T & A, get the Production Cut Date (PCD) & Production Start Date (PSD) from planning.

ii) Make a final costing reviewing Final Tech Pack, re- check fabric consumption and book Fabric and Trims accordingly.

iv) Book Washing, Embroidery /Placement print space if required.

8. Be strict on Materials Inhouse date(MIHD) and make all Fabric and Trims in- house within MIHD to catch PCD.

9. Make C/Sample or Tag/ Sample or PP/Sample with all actual Fabric and Trims.

10. Arrange to do all required Lab Test ( Physical / Chemical) according buyer’s RAS( Risk Assessment Sheet)

11. Send the same Sample to buyer with Lab Test report for reviewing and Comments and finally to get Tag/ Seal.

12. If sample is approved go ahead for bulk Trims as well fabric Dyeing, if not have to re-do.

13. Arrange PP meeting with buyer with Tag sample where all the concerned Production people will be available to make clear in details about the product.

14. Arrange for bulk size set making then Initial Inspection Offer.

15. If Initial Inspection ok, go for Gmts Bulk execution.

16. Do the required Lab test (Physical / Chemical) of Production sample.

17. Send the Production sample with approved Lab Test Report to the buyer for review and approval.

18. Collect the Prod sample approval from buyer and send to Prod. Unit before goods shipment( It’s may vary buyer to buyer)

19. Follow up the bulk execution, keep corresponding with buyer and for any issue arises have to discuss /do meeting with buying office/buyer to solve immediately.

20. Offer Final Inspection to ship out the goods.

21. Follow up the Cargo whether hand over to the forwarded within cut off time or not.

22. Also keep involving yourself with Commercial dept. for the smooth payment receiving from buyer.

🔍 What is Fabric Shrinkage? Shrinkage refers to the reduction in the dimensions (length and/or width) of fabric after it

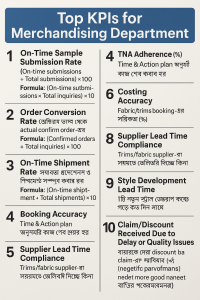

✅ Top KPIs for Merchandising Department (with Bangla Explanation): 1. On-Time Sample Submission Rate📌 সময়মতো বায়ারকে স্যাম্পল সাবমিটের হার📊 Formula:

📖 Index 📚 Introduction of Merchandising 📚 Responsibility of Merchandising 📚 A Merchandiser Daily Work 📚 Email Writing 📚 Marketing

🧾 Garments Cost of Making (CM): Overview In the garment manufacturing industry, CM (Cost of Making) refers to the cost

Empowering learners with curated online courses designed to build real-world skills in just 60 days.